As the Dominican Republic’s economy rapidly develops, the demand for precast concrete blocks across various sectors within the country is steadily rising. Precast concrete blocks are primarily used in two types of construction: ordinary residential buildings and structures for the tourism industry. The Dominican Republic, as a popular tourist destination for people from the U.S., Canada, Europe, and other American countries, is experiencing a rapid growth in tourism, which in turn drives an increased demand for construction and precast blocks. Additionally, other Caribbean countries, due to a lack of local block factories, need to import precast blocks from the Dominican Republic for their construction needs. This high market demand is prompting more industry professionals to establish their own block factories and join the block manufacturing and selling industry.

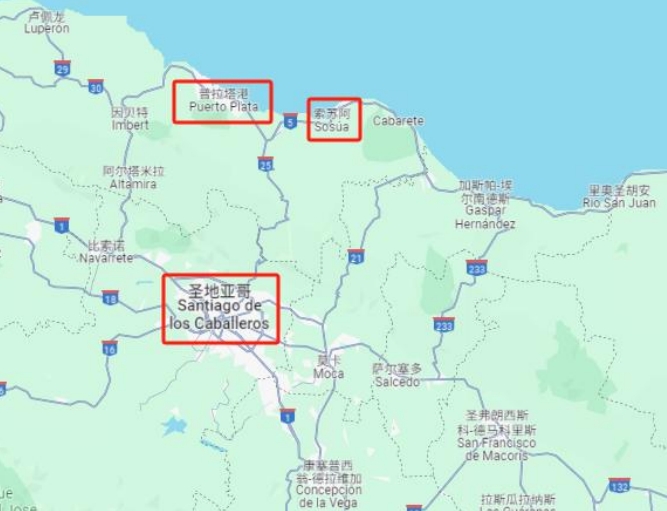

The block machine regions in the Dominican Republic are mainly divided into four major areas:The Capital Region and the Southern Coastal Area, which includes Santo Domingo, San Cristóbal, Bonao, Monte Plata, San Pedro de Macorís, Barahona, etc.;The Eastern Region, which is the most developed area for tourism, includes Punta Cana, Higüey, La Romana, etc.;The Northern Region, which includes Santiago, Puerto Plata, Sosúa, etc.;The Western Region, which is primarily mountainous natural reserves and border areas with Haiti, where there is currently no significant demand.

Block Types:

The 6-inch hollow Block is the most popular, with the South and East mainly using two-hole blocks, and the North using three-hole blocks.The use of 8-inch and 4-inch hollow blocks varies depending on local conditions.Paving blocks are rarely used, as concrete pavement is preferred. However, a small number of producers are beginning to consider manufacturing colored paving blocks.

Materials:

The local concrete materials and recommended proportions do not differ significantly, but in some block factories, the diameter of the raw materials is too large, not fully crushed, and some block factories do not use gravel at all, which are all factors affecting block quality. In the Eastern Region, different types of gravel produce two colors of blocks.

Block Machine Types:

Block factories in the Dominican Republic are generally small to medium-sized and mostly use small, semi-automatic local machines. These machines are expensive, have low output, and produce low-quality finished blocks. Each production line requires 6-8 workers to operate, which increases labor costs. Popular machine models among local customers include QT6-15, QT10-15, QT4-25, etc. However, the demand for machine models varies significantly depending on the market conditions in different regions.

Block Machine Pricing:

According to feedback from customers, the production cost per block is approximately DOP 20-24, around USD 0.34-0.41. The selling price varies depending on customer demand, block quality, market supply prices, and other factors, with an average price of around DOP 35-45, approximately USD 0.59-0.76. blocks from large local factories, due to their higher quality, are sold at even higher prices.

HF Machinery has been deeply rooted in the Dominican market for many years, establishing itself as a trusted and reliable manufacturer of block machines. Over time, the company has developed a comprehensive service system that covers the entire lifecycle of its products, from pre-sales consultations to sales support and after-sales service. This commitment to quality and customer satisfaction has earned HF Machinery high praise from local block manufacturers.

In the pre-sales phase, HF Machinery offers detailed consultations to help customers select the most suitable block machine models for their specific needs. By understanding the unique demands of different regions in the Dominican Republic, HF Machinery provides tailored solutions that maximize efficiency and output for block manufacturers.

During the sales process, HF Machinery ensures smooth transactions and timely deliveries. The company’s strong logistical network allows it to quickly and efficiently supply machines to customers across the country, minimizing downtime and ensuring that production schedules are met.

The after-sales service provided byHF Machineryis one of its key strengths. The company offers comprehensive technical support, including installation, training, and maintenance services. This ensures that customers can operate their block machines with confidence, knowing that HF Machinery is always available to assist with any issues that may arise.

Thanks to its dedicated approach to customer service and high-quality products, HF Machinery has become a respected name in the Dominican Republic’s block manufacturing industry, earning the trust and admiration of local blockmakers.